In the Prusa Mendel variant there are two Z-axis motors, on top of the printer. They are wired in parallel, turning threaded rods connected directly to their drive shafts. They lift and lower the X-axis assembly, which is held in the vertical plane by two vertical rods. This is a much simpler arrangement for the Z-axis, and seems to be working well for others.

The position of the motor drive shaft and the anchor point for the vertical slide rod must be exactly above the matching holes in the X-axis assembly. It helps to line the ends of the x-axis holes up with the z-axis blocks when marking/drilling the x-axis block.

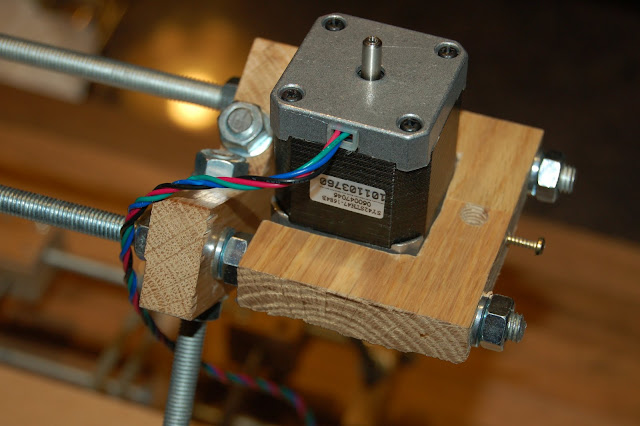

I worked on these blocks at the weekend. Maintaining my wood based construction approach, I cut two 60mm x 80mm blocks with my chop-saw, from my trustee oak floorboard! Here�s my sketch that formed the basis of my plan, and some photos of the steps and finished Z-axis motor mount blocks.

In the RepRap printed version of this part, the large center hold is left much larger, to allow the motor to find it's own center (I gather). I'll see how it goes at 22mm but may have to widen it if my z-travel binds.

I drilled all holes first, then used a router to remove the 42mm square to a depth of 1/2 the block.

I test fitted the motor to ensure a comfortable fit.

I secured the block to the apex-rods. I've decided to use spring washers on all final external nuts - you can see them on the external nuts in this photo. (look like wider washers when squeesed down).It is advised to secure the motor with some tape or strapping but no need to lock it down completely. I'll add something later.

This is what it looks like from the underside. (I made two, once block for each side.)

Feel free to leave a comment or ask a question. Thanks for viewing!