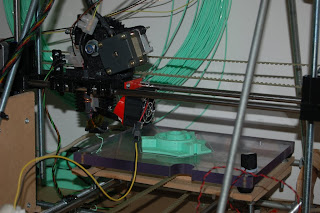

"We have the technology... we can rebuild..."

It's got a new x-end idler. This one http://www.thingiverse.com/image:63587, but instead of fitting real LM8UU linear bearings, I've fitted these printable PLA substitutes http://www.thingiverse.com/thing:12238. We'll see how that experiment goes!

Now, just to mix it up a bit I've put the more traditional x-end motor bracket, http://www.thingiverse.com/image:63177, on the far end, but I've modified it slightly. I'm only using one nut on the z threaded rods. Can't see the point of the second nut and the spring between them. I know it's an anti-backlash design, but I've had only one nut in my wooden design and gravity looks after backlash in the vertical direction. I've no plans to print in zero gravity. :-) Also I couldn't bring myself to use that overhanging motor design, so my motor stays inboard for a more balanced look.

I've retained my wooden z-motor brackets and vertexes(?). They are solid and accurate.

The x-carriage and extruder is now fully RepRap, and as you can see from the part on the bed, I'm printing a spooler!

But a key part of improving print quality has been a fresh examination and fine tuning of basics like squareness, perpendicular z-rods, frame triangle distances all equal. I've screwed the unit to a base board to increase rigidity also. Finally, the introduction of better belt-tensioning technique such as found on Gregs x-carriage, and this little unit (http://www.thingiverse.com/thing:10274) have been invaluable in removing print quality issues due to backlash. The use of these fine tuners allows belt tension to be adjusted a little at a time without over tightening, that might strain something else out of alignment.

Here's a quick look at two test pieces fresh off the newly rebuild rig. I'm pleased with the current print quality.

Now to make it go faster! :-)

Happy printing!

?