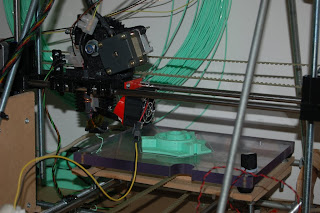

With feedback to my previous post suggesting stationary fender designs of any kind were really the wrong direction to be going to reduce belt friction, I "bit the bullet" this evening and went to work on proper hubs for my idler bearings! Here's one of my new idler hubs now fitted to my y-axis. You'll notice the absence of the large fender washers, and I'm glad to see the back of them! :)

I began by reviewing the existing designs such as this one: http://www.thingiverse.com/thing:503 and this one: http://www.thingiverse.com/thing:3970 and even printed some of them out, but didn't like them so I devised and sketched a split hub design, did some test prints to hone in the dimensions and then knocked out a set...

And here you go... a set of three idler bearings with hubs!

(I'll throw the Sketchup file for the hub design up on Thingiverse in a while. There are many hub solutions, even similar to this one I expect, out there, but no harm is sharing this one also.)

Regards,

NumberSix

I began by reviewing the existing designs such as this one: http://www.thingiverse.com/thing:503 and this one: http://www.thingiverse.com/thing:3970 and even printed some of them out, but didn't like them so I devised and sketched a split hub design, did some test prints to hone in the dimensions and then knocked out a set...

I used the "Multiply" function in Skeinforge to print multiple matching pairs. Then added a dab of adhesive to the inside and clamped them up sandwiching the 608 bearing in the middle.

And here you go... a set of three idler bearings with hubs!

Backing out the threaded rods to remove the fender washers and fit the new hubs to the printer wasn't as big a job as I thought. My printer is screwed to a baseboard so nothing could move very far when I removed the threaded rods. Here's a view of the newly fitted bearing hub from a different angle. The small washers and nuts grip the center hub of the bearing, and the other rim and printed hub are free to rotate smoothly with the belt.

What has struck me is how quick and easy it has now become to devise and evolve a solution, with the combination of a simple drawing package (Sketchup) and the 3D printer at hand!(I'll throw the Sketchup file for the hub design up on Thingiverse in a while. There are many hub solutions, even similar to this one I expect, out there, but no harm is sharing this one also.)

Regards,

NumberSix